Inquire

cone crusher liner profiles

Resolving high wear in cone crushers - Columbia Steel

This is the most common phenomena present in cone liners and the subject we deal with most often when providing our Hi-Pro / H-D liner profiles to customers

Learn More

Cone Crushers | McLanahan

A crusher with coarse style liners would typically have a 6:1 reduction ratio. Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 4.5 inches. Reduction ratios of 8:1

Learn More

cone crusher liner profiles | crusher second pin bush

CS550 CONE CRUSHER. the crushing stages Constant liner profile Maintains the feed opening and performance during the entire service life of the liners Two standard crushing chambers are available for the CS550 and the crusher can easily be matched to changes in production by selecting the right chamber and eccentric throw. The chambers

Learn More

Cone Crusher Liners - Makuri Group

Cone Crusher Liners Makuri provides real solutions for cone crusher liners that go above and beyond the usual OEM standard profiles, leading to measurable improvements and lowest TCO

Learn More

Crushing Chambers – Cones - rockprocessing

We take you through the basics of cone crushing to more detailed advice crushing chamber then you are compromising on productivity, liner life or both.

Learn More

HP series cone crushers Wear parts application

HP cone crusher instruction manual. Before changing the speed of the crusher, consult product support for further information. 6. Check the cavity in use. • Based on feed size • Based on required end product size which determines the required setting range • Check the crushing reduction ratio 7. Check the wear profile of the liners: a

Learn More

Jaw Crusher Liners - Tempus Steel

Selecting the right jaw profile can not only significantly improve jaw crusher performance but also secondary crushing efficiency by generating more accurate

Learn More

Crusher Wear Parts Reference Guide - Corporation

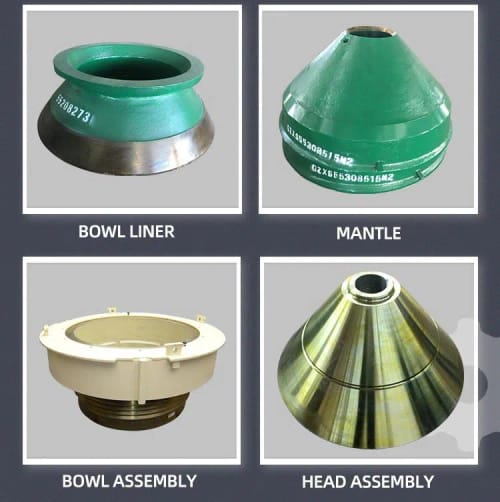

Cone Crusher Wear Parts. 4. Impactor Crusher Wear Parts. Topics within these sections include metallurgy options , liner profiles available , application

Learn More

cone crusher liner profiles | Z276 SQUIRR CAGE MOTOR 55KW(75HP)-380V-50HZ

Examples of calculation results using a cone crusher. Crushing zones, crushing force and esti- mation of wear profile after 10% of liner life used. Crusher Liners | Cone Crusher Liners. description Crusher Liners CSP has been supplying CSP Crusher wear liners for over 30 years to global steel, mining and mineral processing, aggregate, oil sands

Learn More

cone crusher liner profiles | cone crusher apart

CH430 Self-contained cone; Self-Contained Compact Spread; Impact Crushers. Horizontal Impact Crusher. Vertical Shaft Impactor; Screening. About Screening; Incline Screen Plants. 7'x20' 3-Deck Screen Plant; 6'x20' 3-Deck Screen Plant; MS612 High Capacity Multi-Slope Screen Plant; MS612 Feeder Screen;

Learn More

Cone Crushers: The Suppliers' Perspective | E & MJ

cone crushers feature a cam-and-lever crushing action, allowing them to work with many different liner profiles. The company states that in most

Learn More

Cone Crusher - an overview | ScienceDirect Topics

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and steeper cone angles of the breaking head. The approximate distance of the annular space at the discharge end designates the size of the cone crushers.

Learn More

Application guide ® MP Series™ cone crusher wear

The MP Series™ cone crusher is a compressive crusher that crushes feed material between a fixed bowl liner and a movable mantle. Bigger rock particles are crushed directly between the surfaces of the mantle and bowl liner. This is called single-layer crushing.

Learn More

Crushing Chamber Application Guide C5-1086:01ENG

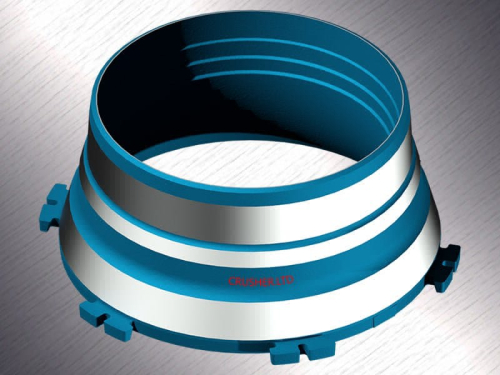

The crushing chamber is the geometric profile between two wear liners. One liner is static while the other is moving. In a cone crusher,

Learn More

PDF Application guide ® MP Series™ cone crusher wear parts - MetsoPDF

Check the crusher operating speed Make sure that the operating speed of the crusher matches the application and liner profile used. 3. Check the cavity in use • Based on feed size • Based on the required end product size which determines the required setting range • Check the crushing reduction ratio 4.

Learn More

cone crusher liner profiles | nordtrack

the crushing stages Constant liner profile Maintains the feed opening and performance during the entire service life of the liners Two standard crushing chambers are available for the CS550 and the crusher can easily be matched to changes in production by selecting the right chamber and eccentric throw.

Learn More