Inquire

jaw crusher toggle plate design

Jaw Crusher - Eastman Rock Crusher

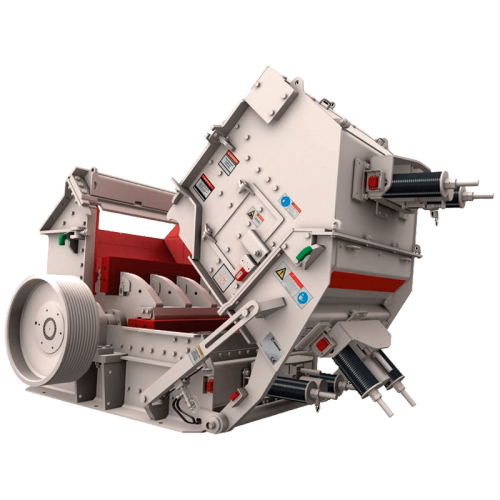

Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.

Learn More

Jaw Crusher Components & Parts - Mineral Processing & Metallurgy

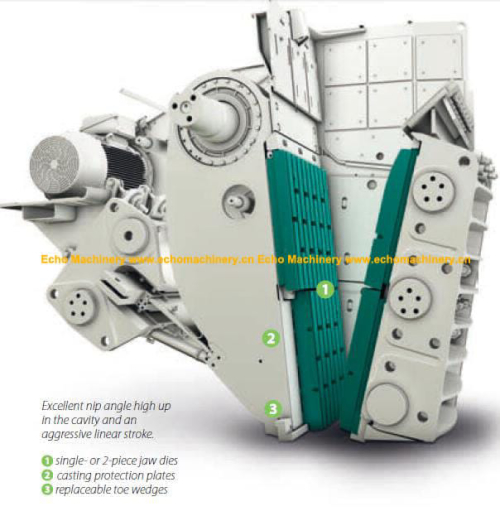

With some designs the toggle plates are made up of two steel plates that are bolted together with what is known as SHEAR BOLTS. These are bolts that have a known shear strength. If something that the crusher cannot crush accidentally gets into the crushing chamber these bolts will shear off when the Jaw hits the unbreakable object.

Learn More

Single Toggle Jaw Crusher With Unique Benefits

Double toggle jaw crusher is designed for the hardest stones and rocks, And when the swing jaw plate leaves the fixed one, the crushed ore is discharged

Learn More

A REVIEW - African Journals Online

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A of the movable jaw, which is controlled by toggle plate and drawback rod.

Learn More

jaw crusher toggle plate design | double toggal jaw crusher spareparts

MEKA Jaw Crushers - Berkshire Engineering Supplies. Single toggle MEKA Jaw Crushers are designed for cost-efficient primary The optimal-angle toggle plate generates extra crushing force and at the same Development design for jaw crusher used in cement. Jaw crusher are classified as follows:- 1.3.1 Blake Type Jaw Crusher .

Learn More

WEAR IN STONE CRUSHER PLATE - IJARIIE

There are two types of jaw crushers : single toggle and double toggle crushers. The double toggle Blake machine is considered the original design of jaw

Learn More

Trio® CT2436 Series Primary Jaw Crusher - The Weir Group

These jaw crushers incorporate steeply designed toggle seats which enable efficient crushing at high production rates. They also feature a fixed jaw die

Learn More

Optimum Design and Analysis of Swinging Jaw Plate of a

Optimum Design and Analysis of Swinging Jaw Plate of a Single Toggle Jaw Crusher Thesis Submitted in Partial Fulfillment of the Requirements for the Award

Learn More

Jaw Crusher Toggle Seat Suit C Series Jaw Crusher Spare Parts - Buy Jaw Crusher Spare Parts

Jaw Crusher Toggle Seat Suit C Series Jaw Crusher Spare Parts Products Description Hyton supplies one-stop service for jaw crusher spare and wear parts, mainly includes: Pitman , Side Plate , Cheek Plate ,Toggle Plate , Flywheel , Wedge , Bearing , Eccentric Shaft, Toggle Plate ,Toggle Plate , Spring , Hopper , End Front and Etc

Learn More

FES | Forrest E. Smith and Sons

Throughout the years, Forrest E. Smith & Sons downsized their product offering and specialized in toggle plates and toggle seats for jaw crushers. Today we offer more than 250 sizes of toggle plates across 19 brands as well as a handful of toggle seats. values Sustain the family legacy by remaining family owned and operated

Learn More

Design of Toggle Plate In Jaw Crusher - CR4 Discussion

3/19 · Design of Toggle Plate In Jaw Crusher 03/19/ 2:22 PM I have a plan to design a new model Toggle plate that helps to perform the crushing operation easily with less power

Learn More

jaw crusher toggle plate design | rock crushers locating bar united states

Design parameters of the single-toggle jaw crusher are: length L and width shape of the longitudinal and transverse profile of the crushing plates [1]. C110 MOTOR M2QA315L4A 160KW german cone crusher socket liner georgia hp 200 boulder crusher parts hp400

Learn More

jaw crusher toggle plates | crusher bearing requirements

Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a moving jaw plates. Our CJ crushers have ***** Jaw shim plate is installed instead of the wear plate. 2 JAW CRUSHER SERIES CSS (MM) CJ211 60 110-160 70 120-180 80 135-205 90 150-230 100 160-250

Learn More

Jaw Crushers– - TerraSource Global

a strong crushing stroke at the top of the jaw plates Additionally, our double toggle jaw crushers do other jaw crusher designs. That's because our.

Learn More

jaw crusher toggle plate design | Walgreens Pill Crusher

The PEV series single toggle Jaw Crusher is a bolted design equipped with two heavy duty non-welded side frames connected to high quality C 106 Toggle Plate Jaw crusheruitable for Nordberg. Jun 17, · US7344097B2 - Jaw-type rock crusher with toggle plate tension Large C jaws (C110 and bigger) were originally designed to use a 2

Learn More

What Are the Functions of Toggle Plate of Jaw Crusher ... - Zoneding

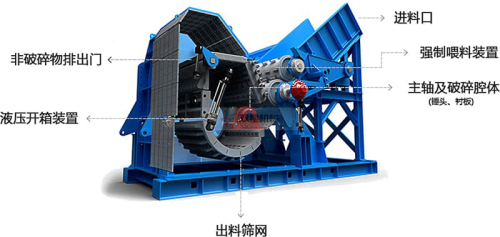

Toggle plate is a power transmission part of jaw crusher. It is used to support movable jaw plate and transmit crushing force to the back of body frame. Adjust discharge opening Adjust the outlet of jaw crusher by way of changing the size of toggle plate. It has two specific ways to adjust the outlet.

Learn More