Inquire

rock crusher liners

Crusher Wear Parts for Popular Crushers | Columbia Steel

from a single manufacturer, anywhere. Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation. Our alloys are tailored to meet the level of impact and abrasion your crushers encounter, resulting in better overall plant performance.

Learn More

Change Cone Crusher Liners - MGS Casting

1. On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been achieved. 2. Keep an exact record of the variety of teeth made use

Learn More

The Value of Wear Liners in Rock Crushing

25/06/ · Wear liners play an important role in rock crushing – and despite their seeming simplicity, they’ve come a long way over the past decade.. To uncover the story behind modern

Learn More

Hillsboro, Oregon - Spray-On Truck Bed Liners | Cornelius, Oregon

Get the quality workmanship you & your truck deserve with a spray in bed liner that lasts ! Xtreme Coatings offers pick up & delivery to your place of business so your rig is prepped, lined & delivered by the end of your work day ! $49.95 Pick Up & Delivery Service. Requires a two man crew pick up process and single crew member return delivery.

Learn More

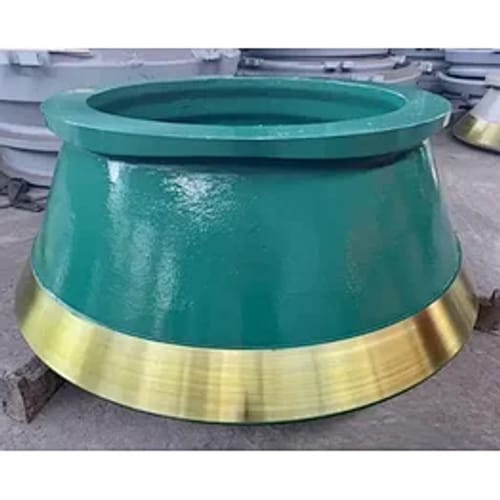

What is a cone crusher mantle? - Sandrock Mining

11/06/ · The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have the characteristics of super wear resistance, high-cost performance, and wide application fields. It is fixed on the cone body by the cone head, and epoxy resin is cast between

Learn More

How Long Should Rock Crushing Equipment Liners Last? - Mellott Company

The key to successful rock crushing lies in sweeping aside systemic inefficiency. We hope this information about rock crushing equipment liners enables you to do just that, through maximized utilization of your wear liners. Make sure your crusher wear liners are correctly utilized—contact Mellott Company for a complete liner study service.

Learn More

Jaw Crusher Liner Plate Design & Profile Shapes

There is one readily discernible difference between the two diagrams we are comparing; the drop per stroke in the jaw crusher diagram is noticeably smaller. This difference is most pronounced in the upper part of the chamber. The reason for the difference is two-fold. In the particular machines selected for these diagrams, there is a difference

Learn More

Rock Crushing Process in Mining - Mineral Processing & Metallurgy

First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher "breaks it and the fine material produced will drop through the gap between the mantle and the liner as it opens. The coarse material that can't fall through will remain to be crushed with the next gyration.

Learn More

Rock Crushers - Best 2022 Models - 911Metallurgist

Rock Crushers for Sale. Rock Crushers for Sale. Showing all 27 results. 1″ x 2″ Mini Rock Crusher. US $ 2,250. Add to cart; Sale! Small Jaw Crusher 2 1/4″ x 3″ US $ 2,500 $ 2,000. Add to cart; 2″

Learn More

rock crusher liners | rockwell milling machine repair head ball

Rock Crusher Lines. 19/8/ · ROCK CRUSHER MACHINES Williams Patent Crusher is proud to offer a line of rock Tips For Buying Crusher Wear Liners. 26/7/ · With C above one per cent and Mn above 11 jaw crusher liner manufacturing process

Learn More

rock crusher liner | crushing equipment copper casting crusher mills cone

The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. EP0093069A2 - Anti-spin device for cone crusher. Anti-spin device for a gyrating rock crusher including a stationary spindle (62) and a referred to as bowl liner (or concave) and mantle, respectively. Change Cone Crusher Liners

Learn More

The Value of Wear Liners in Rock Crushing

25/06/ · Wear liners play an important role in rock crushing – and despite their seeming simplicity, they’ve come a long way over the past decade.. To uncover the story behind modern wear liners, we spoke with Jimmy True, the product manager of wear liners at TEMA ISENMANN, and unpacked how wear liners work, how they provide value, and how they’ve improved over time.

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining

When it comes to crushing blasted hard rock in ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to none. Different Liner configurations etc. Key features. Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h. Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h; Cyclo

Learn More

rock crusher liners | mechanical main shaft bushing machining mini

A crusher is a machine designed to reduce large rocks into smaller rocks and gravel. A wide range of cone crusher liners are available to accommodate coarse and fine feeds, but which you choose stone crushing machine lining stone crushing machine lining. Crushers - All crusher types for your reduction needs - Outotec.

Learn More

rock crusher liners gyratory crusher wear inner bushing from columbia steel

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn More

Crusher - Wikipedia

A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear-resistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl liner. As rock enters the top of the cone crusher, it becomes wedged and squeezed between the mantle and the bowl liner or concave.

Learn More