Inquire

how to make an o-ring seal better

O-Ring Groove Design | Global O-Ring and Seal

Rod Gland Seals: The o-ring OD should be slightly larger than the ID gland depth (max 2%) External Pressure Face Seals: The o-ring ID should be slightly smaller than the gland inner diameter (Gland ID) (max 5%) Internal Pressure FaceSeals: The o-ring OD should be slightly larger than the gland outer diameter (Gland OD) (max 3%)

Learn More

O-Rings? O-yeah! How to Select, Design, and Install O

Mar 24, · When you assemble the components, you need to squeeze the O-ring quite a bit to create a seal. It helps to have a shallow entry angle of about 15 degrees. This surface should

Learn More

How to make an O-ring - O-ring Splice jig

This is a quick video showing how to make your own custom O-ring using the O-ring splice jig. Reduce down time and save money! All of the products and tools

Learn More

Wholesale How To Make An O Ring Seal Better Manufacturer and Supplier

We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for How To Make An O Ring Seal Better, Gear Oil Seal, Remove Bearing Seal Without Damage, O Ring Seal Design, Royal Enfield Front Fork Oil Seal Price. Living by good quality, enhancement by credit history is our

Learn More

3 Guidelines to Ensure Proper O-Ring Installation

Dec 19, · O-Lube has a recommended service temperature of -20°F to 180°F (-29°C to 82°C). On the other hand, Super-O-Lube is an ideal all-purpose O-ring lubricant. Rather than a grease, the Super-O-Lube is a high viscosity silicone oil. It is an extremely effective seal lubricant, useful from -65°F to 400°F (-54°C to 204°C).

Learn More

O-ring Seal Design Best Practices - HpAEC

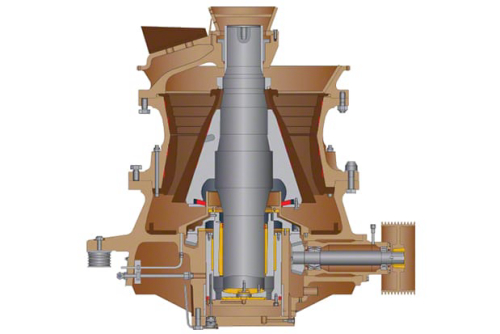

An o-ring seal consists of an o-ring and a properly designed gland which applies a predictable deformation to the o-ring. The gland is basically a groove dimensioned to a certain height “H” and width “W” (Figure 1) to allow a fixed compression of the o-ring when the gland flanges make metal to metal contact.

Learn More

How To Swell A Rubber O Ring - Xiamen YJC Polymer

Sep 18, · One can also consider a type of rubber that has been shown to be spiral-stable without lowering the seal performance. You can pull out the O-ring and place an additional flat

Learn More

Spring Energized Seal vs. O-Ring: Which is Better?

Nov 22, · A Spring Energized PTFE or UHMW-PE seal can provide long-lasting sealing performance in applications where an O-Ring would be shredded in minutes. The higher the speed of the motion, whether reciprocating or rotary, the more likely a Spring Energized Seal will be needed. PTFE’s ability to run without lubrication also presents a distinct advantage.

Learn More

Details Home - Parker Hannifin

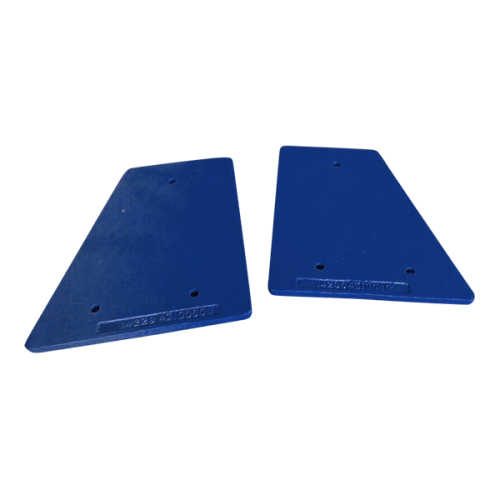

The flexibility on the sizing of precision cut seals allows us to change the square to a rectangle, or other configuration, as an alternate seal solution if it better suits the preexisting groove. This customization can be a great alternative for unconventional groove profiles where an O-ring simply will not work.

Learn More

how to make o rings Manufacturers and Factory China - Customized

This how to make o rings from Yiho Polytek enjoys the advantages of high ozone and chemical resistance, good flexibility and elasticity, excellent oil resistance, etc. We have been specialized in manufacturing quality rubber products since 1994. Providing you with timely online service and quick delivery, we warmly welcome you to buy our products.

Learn More

How to - Maintenance and Care Procedures for O-Ring Seals

Sonardyne 1.42K subscribers We recommend that every time you open up a Sonardyne transponder to service it, you perform these basic, but very important checks. The advice in this video is common to

Learn More

Everything You Need To Know For Easy O-ring Installation

Engineers need to ensure that the stretch does not go beyond the maximum elongation of the O-ring. It's also important to stretch the O-ring evenly, not just on one side or the other. In general, try to stretch the O-ring as little as possible for a tighter fit. Slide, Don't Roll: Rolling an O-ring down a shaft for installation leads to

Learn More

Enhancing An O-Ring Seal? - Google Groups

May 25, · For most o-ring situations, the preferred lube is "high-vacuum silicone grease". But it is expensive. Plumber's silicone grease is a good substitute. But before you goop things up,

Learn More

O-Rings? O-yeah! How to Select, Design, and Install O-Ring Seals

In addition to lubricating the rubber and helping it slide in easier, most O-ring grease is designed to cause the O-ring to swell slightly, helping increase the squeeze after installation. When you assemble the components, you need to squeeze the O-ring quite a bit to create a seal. It helps to have a shallow entry angle of about 15 degrees.

Learn More

O-rings, Quad Rings, Encapsulated orings

An O-Ring functions as a seal through the mechanical deformation of the elastomeric compound by mating metal surfaces. This creates a condition of "zero" clearance which blocks the liquid or gas being sealed. The pressure which causes the O-Ring to move is supplied by mechanical pressure or "Squeeze" generated by proper gland design

Learn More

How To Make An O Ring Seal Better - Choi Alitch

Dec 01, · Another great trick to ensure proper O-ring installation is to install the O-ring according to the manufacturer's good design practices. For example, you should consider the defined O-ring dimensions to uphold adequate compression on the O-ring without surpassing the capacity of the grove. Find Out More Here! Use the Right O-ring Lubricant

Learn More