Inquire

impact crusher pdf

Influence of Crusher Machinery & It's Working Principle - IRJET

categories i.e. Cone crusher, Jaw crusher and Impact crusher. However, there are few studies of crushers mechanism like jaw crusher, horizontal shaft.

Learn More

Design of impact stone crusher machine - Citefactor

Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides

Learn More

PDF HAZEMAG Secondary Impactor | APS, APSM - Rolling Rock EquipmentPDF

Impact Crusher is ideally suited for crushing medium-hard rock down to a well graded, highly cubical product size of 0 - 3 inch. Due to its operational flexibility, economically operation and excellent product size control, this machine is widely accepted as the machine of choice for the North American Aggregate Industry.

Learn More

Impact crushers - thyssenkrupp

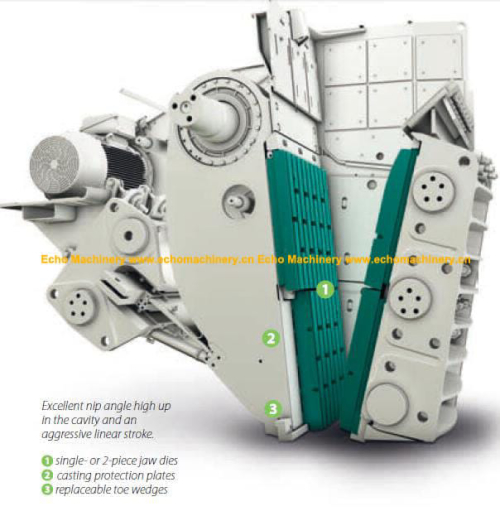

thyssenkrupp impact crushers are suitable for both coarse and fine crushing. From top: Stationary single-shaft impact crusher fed by two apron feeders at

Learn More

EV hammer impact crusher

The crusher therefore has to handle feed containing fairly large blocks as well as some sticky materials. The proven and reliable EV hammer impact

Learn More

PDF) A performance model for impact crushers - ResearchGate

In this paper we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher's

Learn More

Impact Crusher Working Principle - Mineral Processing & Metallurgy

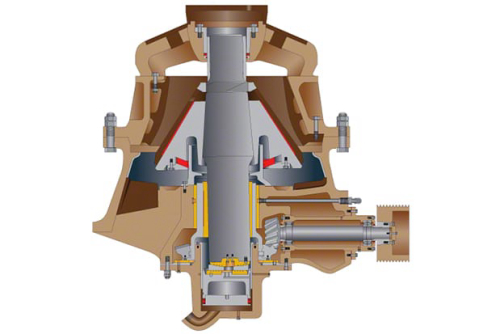

Dynamic impact could be described as material dropping into a rapidly turning rotor where it receives a smashing blow from a hammer or impeller. Attrition crushing is the reduction of materials by rub ; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage.

Learn More

Impact crushers - high-quality impactors - Outotec

Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each other.

Learn More

PDF Design and Analysis of A Horizontal Shaft Impact CrusherPDF

Impact crushers involve the use of impact rather than pressure to crush materials. Here the material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through them. This type of crusher is generally used with soft materials like coal, seeds or soft metallic ores.

Learn More

PDF IMPACT CRUSHERS - PECO Sales & RentalPDF

The 4800 Series Impact Crushing Plants from Lippmann are the ultimate, completely self-contained, easy to transport crushing plants that offer the features contractors need, like a larger crusher feed opening that devours concrete full of rebar, ripped asphalt and other C&D debris. The heart of the plant is a Lippmann 4248LP Impact Crusher, a

Learn More

VERTICAL SHAFT IMPACT CRUSHER SERIES - KPI-JCI

Consult KPI-JCI's entire VERTICAL SHAFT IMPACT CRUSHER SERIES catalogue on DirectIndustry. Page: 1/6.

Learn More

PDF 1516 GRADATION CURVE AND CHART - ICM CavePDF

HSI 4143 Impact Crusher Flexible. Cost effective. Responsive. With its hydraulic assist apron adjustment for quick setting changes, the 4143 horizontal shaft impactor is a highly cost effective crusher that is easy to operate and easy to maintain. There are four inspection doors plus a hinged side door for

Learn More

PDF Impact crushers NP Series impact crushers - International Crusher SolutionsPDF

NP impact crushers have proven their effectiveness in a host of missions from crushing low abrasive materials to industrial applications and recycling. 5 Process benefits • High reduction ratio. • Good cubical shape to meet asphalt and concrete product specifications for flakinessand elongation.

Learn More

IMPACT CRUSHERS - PSP Engineering

The material is disintegrated by means of the rotating bars and impacts from the fixed plates. Impact crushers are manufactured with capacities ranging from

Learn More

1516 GRADATION CURVE AND CHART - ICM Cave

Cedarapids IP 1516 Impact Crusher Power. Volume. Control. With its large feed opening, large capacity and high reduction ratio, the ® Cedarapids 1516 horizontal shaft impactor delivers extraordinary crushing power, plus high production volume. Rapid blowbar and quick change breaker plates allow for better control of product size.

Learn More

PDF Design of impact stone crusher machine - CitefactorPDF

Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through them. Impact stone crusher is used with soft materials, medium to hard stones and medium hard metallic ores.

Learn More