Inquire

primary crusher design aggregates pdf

Optimization of Aggregate Production Circuit through ... - MDPI

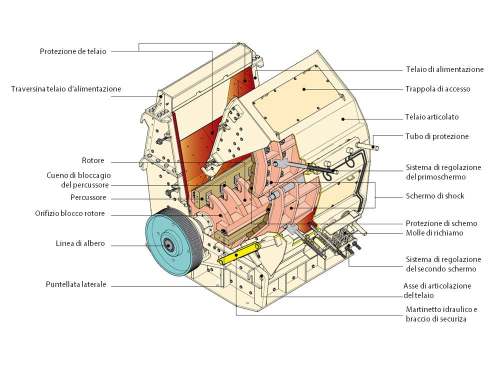

Abstract: The paper concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral

Learn More

Crushing Plant Design and Layout Considerations

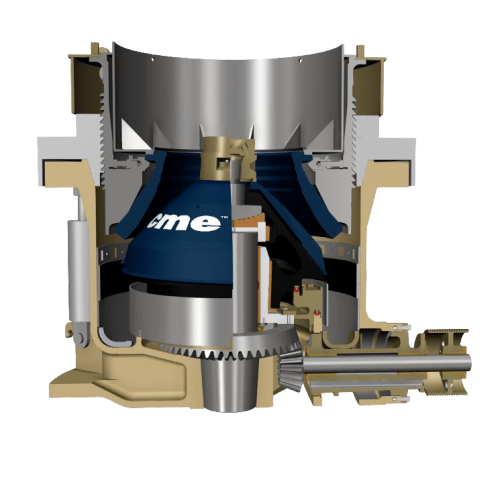

The largest primary gyratory crushers cost US $2 million or more, while overall crushing plant costs can be as high as $18 million. It’s necessary therefore to estimate crusher installation

Learn More

Energy Efficiency Opportunities in the Stone and Asphalt

Details on the different available crusher designs are presented below. 1. Jaw Crushers. Jaw crushers are typically used as primary crushers. A jaw crusher.

Learn More

PDF Design of a crushing system that improves the crushing efficiency of ...PDF

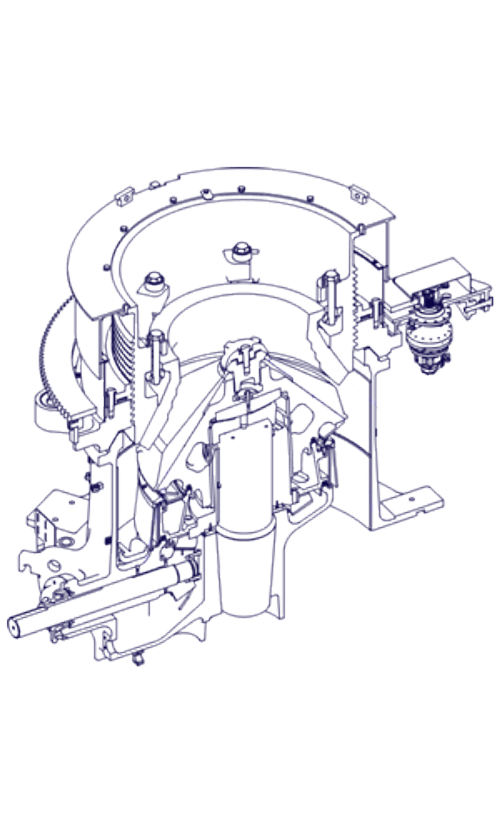

has to follow these three steps: crusher selection, crusher layout and process design. 2.4 Crushers . A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle. The ore can have a size of up to 400mm. There are many types of crushers but the major ones are the jaw, gyratory and the cone

Learn More

Used Crusher Aggregate Equipment For Sale in ARLINGTON, TEXAS - 79

Browse a wide selection of new and used Used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from , , and KLEEMANN, and more, for sale in ARLINGTON, TEXAS

Learn More

Aggregates for Concrete, Chapter 5 - Civil Engineering

Crushed stone is produced by crushing quarry rock, boul- ders, cobbles, or large-size gravel. design. It is not generally used as a measure of aggregate.

Learn More

PDF) Measuring characteristics of aggregate material from

The vertical shaft impact crusher (VSI) produces gravel that is a good alternative to natural gravel. The quality of the material and the

Learn More

A CASE STUDY ON VERTICAL SHAFT IMPACT C - DergiPark

vertical shaft impact crushers, rock aggregate quality was investigated for rock aggregates produced through jaw and cone crushing circuits have a

Learn More

PDF Handbook of Crushing - TerraSource GlobalPDF

Primary Crusher— The first crusher in a crushing system into which material is fed. Succeeding crushers in the system are referred to as secondary or tertiary crushers. Product— Output from the crusher. Reduction Ratio— The ratio of the top size of input material to the top size of crusher discharge.

Learn More

Simplification of Jaw crusher for Artisanal Aggregates Miners

artisanal miners, mostly women, who spend long hours in quarrying sites excavating and crushing aggregates using manual tools. The aim was to design a

Learn More

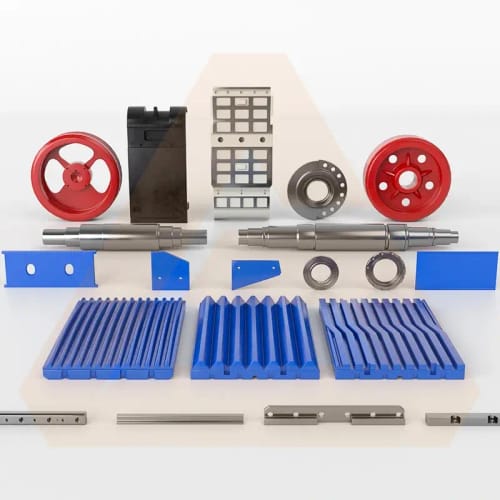

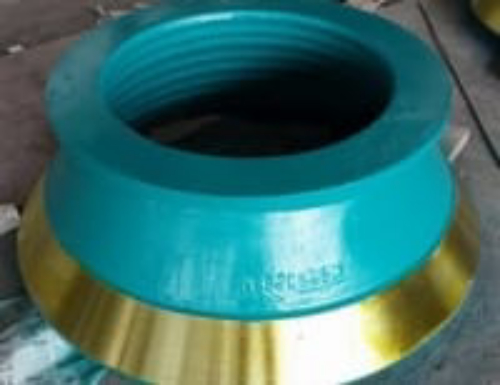

crusher cone liner | primary crusher design aggregates pdf

The HP cone crusher is a very important piece of equipment in a crushing plant. It can operate as a secondary, tertiary or quaternary cone crusher operation with best quality cone crusher wear parts primary crushers hp400 tube G10SEC DRCTNLVALVE&CNNCTN CVUA-6-PDN-2-M-U-D-1 thermomax hp400 evacuated tube collectors

Learn More

pit-and-quarry-january-2011.pdf - Palm Beach Aggregates

producing aggregate products, plus a portable. 500-tph primary impactor crushing base rock design the plant I envisioned, or it would.

Learn More

Construction Working and Maintenance of Crushers for Crushing

Primary Crusher The first crusher in a crushing system into which material is fed. Succeeding crushers in the system are referred to as secondary (second), tertiary (third) or quaternary (fourth) crushers. Reduction Ratio The ratio of the top size of input material to the top size of crusher discharge material. Run of Mine (ROM)

Learn More

Aggregate Crusher Plant Design Pdf

Stone Production LineOre CrusherRock Crushing PlantCrusher. Crushing Plant Design and Layout Considerations PDF Download 2.05M Fill in your email address and click on download.We will provide you with the best.

Learn More

Primary crusher, Primary crushing and screening plant - All

TECHNICAL SPECIFICATIONS: - Bunker: 20 m3 - Plant Dimensions (1st chassis): 11000x3450x4600 mm - Second chassis: 15300x4250x4600 mm - Production Capacity: 100-180 Tons Per Hour - 1st Crusher: jaw crusher K series mobile primary secondary Capacity: 100 t/h -

Learn More

Report - SINTEF

5.1 Primary crushing . 5.2 Cone and gyratory crushers . 8.3 Aggregate quality achieved with portable crushing plants .

Learn More