Inquire

rock crusher cone liner

What is a cone crusher mantle? - Sandrock Mining

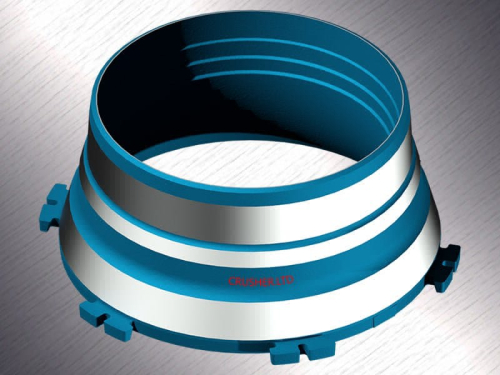

The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have the characteristics of super wear resistance, high-cost performance, and wide application fields. It is fixed on the cone body by the cone head, and epoxy resin is cast between

Learn More

Prolonging Cone Crusher Liner Life - Agg-Net

On most cone crushers, rough-cast manganese liners are fitted to the head assembly and Rock with a low silica content, eg good-quality limestone,

Learn More

rock crusher liner company profile

EP0093069A2 - Anti-spin device for cone crusher. Anti-spin device for a gyrating rock crusher including a stationary spindle (62) and a referred to as bowl liner (or concave) and mantle, respectively. JBradley Aggregate Mechanics. Liner Changes and Internal Crusher Inspections We can Install Liner's in various Rock crushers, OEM or

Learn More

Products | Crushing | Cone Liner - Southern Ferro Steels Ltd

Southern Ferro Steels Ltd manganese steel crusher liners are independently proven in mining & rock crushing production to achieve and often exceed the

Learn More

When do you change cone liners? - ELRUS

We believe the maximum threshold for a liner change is as follows: Change your liners no later than a 10% decline in production. Why? Production rate: 200 tons per hour of sellable? minus Crush Margin $2.50 per ton hours per day 10 production hours per day. Therefore a 10% reduction in production results in a loss of $2,000 per day in gross profit.

Learn More

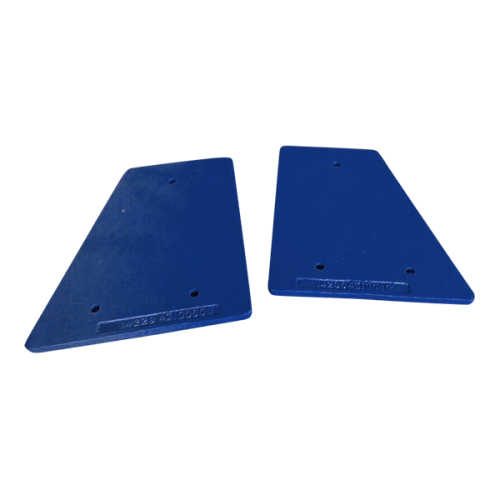

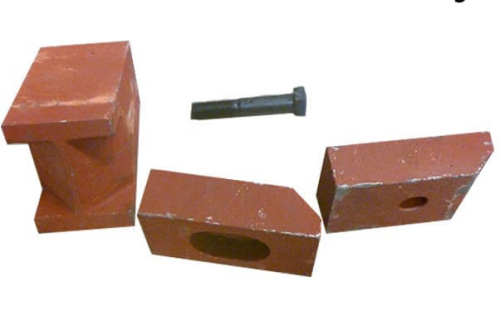

rock crusher cone liner | cone crusher eccentric upper head bushing

Rock crushers; Manteinance; Spare parts; 53- Socket liner for 3' cone. 54- Socket liner for 4.25' cone. 55- Toggle plate for 16x24 jaw. 56- Toggle plate for 24x36 jaw. 57- Toggle plate for 30x42 jaw. 58- Jaw tension rod, 46 x 790 mm. 59- Liner square taper head bolts, 28 x 110 mm. 60- Liner bolts, 28 x 253 mm

Learn More

Change Cone Crusher Liners - MGS Casting

1. On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been achieved. 2. Keep an exact record of the variety of teeth made use of to compensate for liner we this set of liners. 3.

Learn More

rock crusher cone liner | crusher main centrifugal casting south africa

CH430 Self-contained cone; Self-Contained Compact Spread; Impact Crushers. Horizontal Impact Crusher. Vertical Shaft Impactor; Screening. About Screening; Incline Screen Plants. 7'x20' 3-Deck Screen Plant; 6'x20' 3-Deck Screen Plant; MS612 High Capacity Multi-Slope Screen Plant; MS612 Feeder Screen;

Learn More

Cone crusher basics in 4 minutes — SRP

The CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher. Sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feed.

Learn More

rock crusher cone liner | sl high speed radial spherical roller bearing

Cone crushers Wear parts application guid 2018. The HP cone crusher is a compressive crusher in which feed material is crushed between a fixed bowl liner and a moveable mantle. Bigger rock Crusher Liners | Cone Crusher Liners. 932 rows · description Crusher Liners CSP has been supplying CSP Crusher wear

Learn More

rock crushing cone liners

Cone Liners - 888 Crushing & Screening Equipment. Jaw Plates - Cone Liners. 888cse can currently offer exceptionally competitive prices for very high grade 22% Manganese Jaw Plates and Cone Crusher Liners. how to install liners in cone crushers - how to install liners in cone crushers Grinding Mill China.

Learn More

Rock Crushers - Best 2022 Models - 911Metallurgist

Rock Crushers for Sale Showing all 27 results. 1″ x 2″ Mini Rock Crusher. US $ 2,250. Add to cart Cone Crushers >50 TPH. US $ 150,000. ALL LABORATORY CRUSHERS. Read more;

Learn More

Prediction of Cone Crusher Performance Considering Liner

Cone crushers are used in the aggregates and mining industries to crush rock material. The pressure on cone crusher liners is the key factor that influences

Learn More

Crusher Wear Parts for Popular Crushers | Columbia Steel

Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation. Our alloys are tailored to meet the level of impact and abrasion your crushers encounter, resulting in better overall plant performance. For gyratory, cone, jaw, hammer mill, impact

Learn More

rock crusher cone liner | fruit press

US20050269436A1 - Cone rock crusher. An improved cone-style rock crusher. The rock crusher may be adjusted for varying rock crushing specifications, including different speeds, throws,

Learn More

Cone crusher parts - Wear Parts For Industry | Qiming Casting

This Mn18Cr2 cone crusher liners widely in crushing difficult and non-abrasive blasted rock, medium and non-abrasive,non-abrasive gravel, and non-abrasive round rock. Mn22Cr2. Mn22Cr2 cone crusher liners are widely used in crushing hard and abrasive stones. Under our technology, its span life much better than normal. Alloy steel. Alloy steel to

Learn More